Duplex Heat Exchanger Tubes

What are Duplex Heat Exchanger tubes ?

A Duplex heat exchanger is a high-performance thermal device made from duplex stainless steel, known for its unique combination of strength and corrosion resistance. The material’s dual-phase structure—consisting of both austenite and ferrite—provides enhanced durability and excellent resistance to stress corrosion cracking, pitting, and crevice corrosion, particularly in environments with high chloride levels or aggressive chemicals.

This makes Duplex heat exchangers ideal for critical industries such as oil and gas, chemical processing, power generation, and marine operations. Their superior mechanical strength allows for more compact designs with thinner walls, reducing overall weight and material costs without compromising performance. With a strong balance of efficiency, longevity, and resilience under pressure, Duplex heat exchangers are a smart, reliable choice for demanding heat transfer applications.

DSS boiler tube and duplex finned tube manufacturer in India

What are the requirements for surface finish and cleanliness of Duplex stainless steel finned Tubes?

✅ Smooth Surface: The tubes should have a clean, smooth, and uniform surface without scratches, dents, or visible defects.

🚫 Free from Contaminants: No oil, grease, dirt, dust, or metal particles should be present on the surface.

🧪 Pickling and Passivation: These chemical treatments are often used to clean the surface and enhance corrosion resistance.

📏 Controlled Roughness: Surface roughness (Ra) should meet the required standard—usually smoother surfaces are needed for critical or hygienic applications.

🔍 Thorough Inspection: Tubes should be visually inspected and, if necessary, tested to ensure proper cleanliness and finish.

📜 Standards Compliance: Cleaning and surface finish should comply with relevant industry standards like ASTM A380, A967, or customer specifications.

💡 Application-Specific Requirements: Stricter cleanliness may be needed for industries like food, pharmaceuticals, or high-corrosion environments.

Read advantages of duplex 2205 condenser tubes and duplex stainless steel finned tube with competitively priced and offer long-term cost savings..

DSS Condenser tubes

Duplex steel boiler tube

Duplex ss heat exchanger tubing

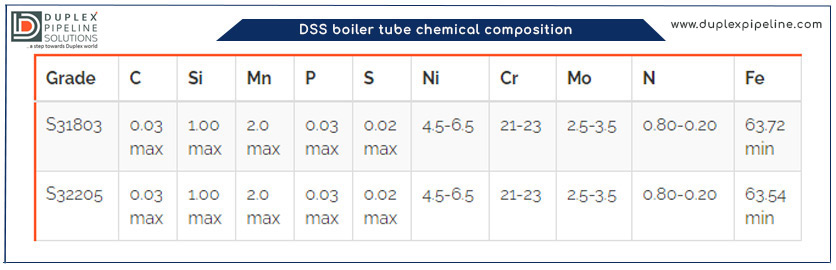

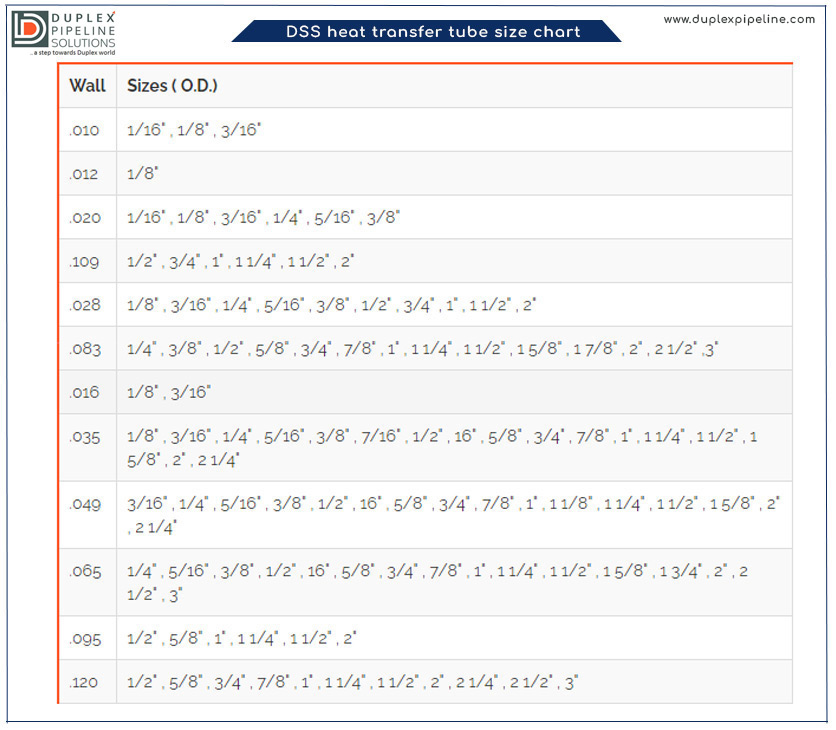

What sizes of duplex DSS boiler tube are available?

These tubes are typically manufactured in accordance with standards such as ASTM A789, ASTM A790, or ASME SA789/SA790. For specific sizes, tolerances, or custom requirements, it’s best to consult with the manufacturer.

UNS S31803 u shaped heat exchanger tubing and duplex heat transfer bundles can be made to any size to suit a variety of needs.

We are best quality duplex heat exchanger tubes manufacturer in India

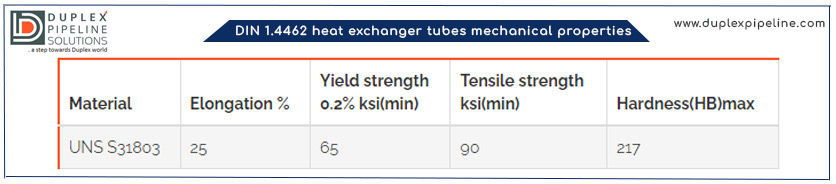

DIN 1.4462 evaporator tubes offer excellent corrosion resistance in harsh environments

Duplex steel u tube

- OD: 5.0mm – 203.2mm

- Finish: Bright & Annealed

- Form: square, hollow, round

Duplex heat transfer bundles

- Wall thickness: 0.5mm to 20mm

- Length: Standard & Cut length

- Application: Oil and Gas

DSS double Tube Condenser

- Pipe Schedule: XS, SCH10S, SCH5, SCH60, SCH80

- End: Plain, Beveled

- Type: ERW/ Seamless /EFW

View mechanical properties of duplex steel u tubes and S32205 heat exchanger tubing

What are Unique properties of Duplex Condenser Tubes?

🔹 1. Exceptional Corrosion Resistance

Duplex condenser tubes offer excellent resistance to pitting, crevice corrosion, and stress corrosion cracking—particularly in chloride-rich environments like seawater and cooling systems.

🔹 2. High Mechanical Strength

They have nearly twice the strength of austenitic stainless steels, allowing for thinner wall designs without compromising performance, which reduces weight and cost.

🔹 3. Excellent Thermal Conductivity

Despite their strength, Duplex tubes maintain good thermal conductivity, ensuring efficient heat transfer in condenser systems.

🔹 4. Long Service Life

Their ability to withstand aggressive media and high mechanical stress ensures long-term durability and lower maintenance needs.

🔹 5. Resistance to Erosion and Fatigue

Duplex stainless steel has strong resistance to erosion, vibration, and thermal fatigue—critical factors in condenser and heat exchanger performance.

🔹 6. Weldability and Fabrication

With proper techniques, Duplex condenser tubes can be easily welded and formed, making them suitable for complex system installations.

What are the advantages and cost of Duplex steel reheater tubes compared to other materials?

✅ High Strength with Less Weight

Duplex steel is nearly twice as strong as traditional stainless steels, which means thinner, lighter tubes can be used without compromising performance. This not only saves material costs but also improves the overall design and weight distribution of the system.

🌊 Excellent Corrosion Resistance

It offers superior protection against pitting, crevice corrosion, and stress corrosion cracking, making it ideal for harsh environments where corrosion is a serious concern.

🔧 Reliable Weldability

Duplex steel can be welded using standard processes, provided proper welding practices are followed. This makes fabrication and installation more efficient.

🔄 Versatile and Flexible Use

Thanks to its strength and corrosion resistance, duplex steel works well in many applications—like heat exchangers, piping, and other industrial equipment.

💰 Cost-Effective Material Choice

While the upfront cost may be slightly higher, duplex steel typically contains less nickel and molybdenum than austenitic grades. This can lead to savings, especially when alloy prices are high.

🔧 Better Uptime and Reliability

Its resistance to corrosion means fewer failures and longer operational cycles, which translates to more uptime and fewer interruptions in service.

📏 Compact Designs and Less Welding

Because of its strength, designers can use smaller tube sizes and thinner walls. This leads to more compact systems and can also reduce the amount of welding required during installation.

🛠️ Long-Term Savings

Duplex steel’s durability means lower maintenance needs and a longer equipment lifespan, helping reduce overall costs over time.

📉 Upfront Cost Awareness

Although duplex steel may cost more initially than materials like carbon steel, its long-term benefits and lower alloy content can make it a smarter investment overall.

What is the maximum temperature that Duplex Steel u tubes can withstand?

Duplex steel U-tubes are designed to perform exceptionally well in high-temperature environments, but like all materials, they have a thermal limit. Generally, duplex stainless steels can withstand temperatures up to approximately 280–315°C (536–600°F) during continuous operation. Beyond this range, prolonged exposure may lead to the formation of detrimental intermetallic phases, which can reduce corrosion resistance and mechanical strength.

However, some advanced grades, such as Super Duplex, can tolerate slightly higher temperatures for short durations, depending on the specific application and environment. It’s important to note that the maximum service temperature also depends on factors like pressure, exposure time, and the corrosive nature of the operating environment.

To ensure long-term reliability and performance, it’s recommended to consult relevant material standards and work closely with the tube manufacturer when selecting duplex U-tubes for high-temperature applications.

Why To Choose Our Duplex Heat Exchangers Tubes?

✅Durable & Long-Lasting

✅Certified Quality

✅Custom Sizes Available

✅Timely Delivery

✅Full Traceability

✅Expert Support

✅High Strength